The Problem

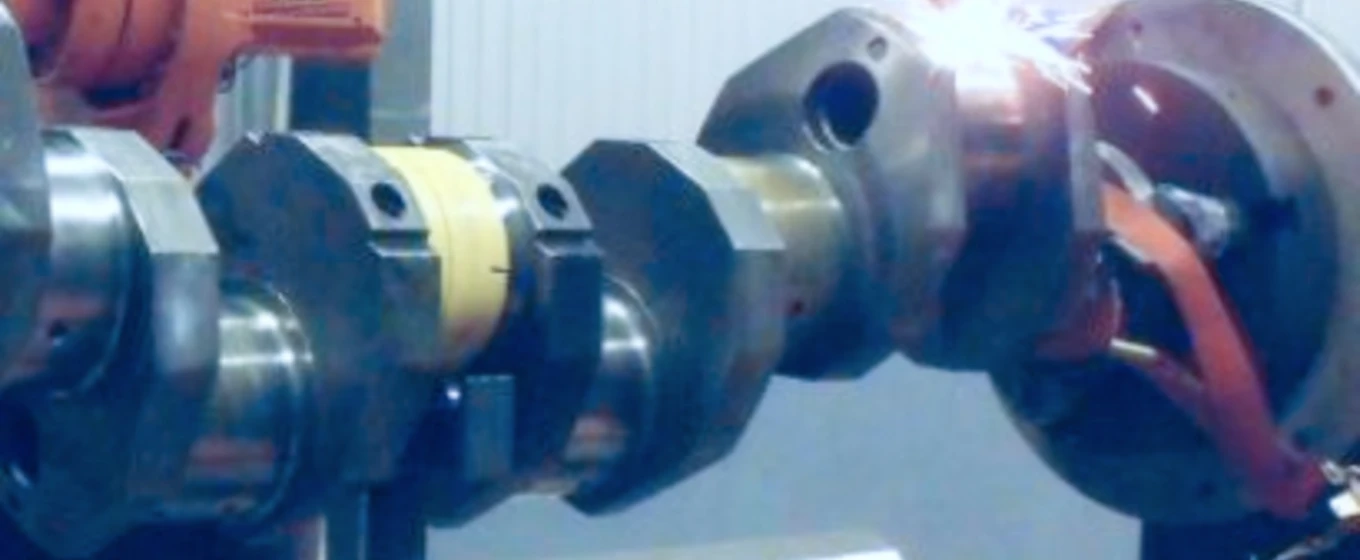

As the eastern markets closed off in terms of deliveries of spare parts for locomotives used in rail transport, it became necessary to either withdraw the existing rolling stock or to find an effective way to solve the problem of refurbishing used parts. While the refurbishing of main crankshafts was relatively easy, the refurbishing of crankpins required innovative technologies based on robotic lines to provide pad welding along a very precise eccentric trajectory.

The Results

With its unique infrastructure and competences, Plasma System was able to provide an effective solution based on laser technologies. This solution enables us to refurbish the crankpin using low-energy laser pad welding technology, which makes it possible to achieve maximum axiality without the risk of distortion of the finished component.

The component, after refurbishing and final machining of the crankpin, can practically be reinstalled directly into operation, without the need of any additional processing. The properties of the refurbished component are the same as the properties of a newly manufactured part