Industry challenges

In everyday operation, this involves a sharp increase in the corrosion of boiler and pipe screens through the destructive effects of chlorine and sulphur. On the other hand, the consequence of restrictive EU regulations limiting the level of nitrogen oxide emissions to the atmosphere is the intensification of low-oxygen corrosion.

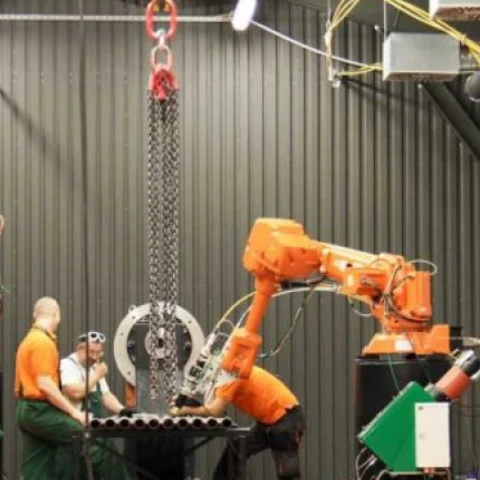

To meet the expectations of our clients in the energy sector, we have developed and implemented for use unique protective coatings which are protected by our patents and increase the resistance of protected surfaces in difficult conditions. Depending on the conditions of the erosive-corrosive environment and the nature of the components' wear, we offer solutions tailored to the needs of your organisation.

Coatings offered:

- Highresist®

- Plasmadur®

- Protector®

- Inconel 625

We are also able to develop individual protective coatings for specific working conditions.

Our coatings effectively protect energy devices against various adverse phenomena, such as:

- High-temperature and low-oxygen corrosion

- Erosion

- Abrasive wear

- Cavitation

Solutions effectively protect surfaces, including elements such as: dust boiler screens, fluidized bed boiler screens, superheater tubes, dust pipe components, blind devices, mill fans, ICL burners, endless screws of coal feeders, elements of ash extraction systems, fans, flue gas ducts, cyclones, and others. We are also able to develop individual protective coatings for specific working conditions.